Ball valve

We offer a wide range of ball valves from an array of top-quality ball

valve manufacturers. Ball

valves from us are durable, reliable, and built to last.

Floating, Trunnion, Rising Stem, Dual Piston Effect, Top Entry

Forged and Cast

Forged and Cast Flanged, Threaded, HUB,

Socket & Butt-Welded ends.

Flanged, Threaded, HUB,

Socket & Butt-Welded ends. Size from 1/4″ to 56″

Size from 1/4″ to 56″ Class from 150 up to 4500

Class from 150 up to 4500

Soft or metal seated.

Soft or metal seated. Reduced or full bore

Reduced or full bore Fire Safe

Fire Safe Anti Blowout Stem

Anti Blowout Stem Antistatic Device

Antistatic Device Operating temperatures:

-196°C – + 788°C

Operating temperatures:

-196°C – + 788°C Materials: LTCS, CS, SS,

Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Materials: LTCS, CS, SS,

Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Butterfly Valves

We are a supplier of Butterfly valves to the oilfield, petrochemical,

waste, and water sectors

in Saudi Arabia. Our valves are one of the most durable of all resilient-seated

butterfly valves in the

industry, the butterfly valve excels in a wide variety of applications.

Concentric, Double, and Triple Offset

Flanged, Lug, Wafer, HUB,

Socket & Butt-Welded ends.

Flanged, Lug, Wafer, HUB,

Socket & Butt-Welded ends. Size from 2″ to 112″

Size from 2″ to 112″ Class from 150 up to 4500

Class from 150 up to 4500

Operating temperatures:

-196°C – +788°C

Operating temperatures:

-196°C – +788°C Materials: LTCS, CS, SS,

Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Materials: LTCS, CS, SS,

Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Gate Valves

Our Gate Valves are from genuine guaranteed raw material with material

test certificates,

hydraulic test certificates, and MTC 3.1 available with all supplies. Also, we can

provide valves with

third-party inspection agencies.

Wedge, Dual Expanding, Parallel Slide, Thru Conduit

Flanged, Threaded, HUB,

Socket & Butt-Welded ends.

Flanged, Threaded, HUB,

Socket & Butt-Welded ends. Size from 1/4″ to 56″

Size from 1/4″ to 56″ Class from 150 up to 4500

Class from 150 up to 4500

Operating temperatures:

-196°C – +788°C

Operating temperatures:

-196°C – +788°C Materials: LTCS, CS, SS,

Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Materials: LTCS, CS, SS,

Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Globe valves

Globe valves are designed to stop, start, and regulate flow within a

pipeline, by means of

throttling and isolation. These types of valves can be used in application with

marine ballast systems, as

well as heating and air conditioning, water distribution and/or treatment, and much

more.

Flanged, Threaded, HUB,

Socket & Butt-Welded ends.

Flanged, Threaded, HUB,

Socket & Butt-Welded ends. Size from 1/4″ to 56″

Size from 1/4″ to 56″ Class from 150 up to 4500

Class from 150 up to 4500

Operating temperatures:

-196°C – +788°C

Operating temperatures:

-196°C – +788°C Materials: LTCS, CS, SS,

Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Materials: LTCS, CS, SS,

Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

DESIGN AND MANUFACTURING

BS 1873:

Steel Globe And Globe Stop And Check Valves (Flanged And Butt- Welding

Ends) For The Petroleum,

Petrochemical And Allied Industries.

BS 1873:

Steel Globe And Globe Stop And Check Valves (Flanged And Butt- Welding

Ends) For The Petroleum,

Petrochemical And Allied Industries. B 16.34:

Valves-Flanged, Threaded, and Welding End.. B5-5352 (replaced by ISO

15761).

B 16.34:

Valves-Flanged, Threaded, and Welding End.. B5-5352 (replaced by ISO

15761). ISO 15761:

Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for

the Petroleum and Natural

Gas Industries (Equivalent to API 602).

ISO 15761:

Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for

the Petroleum and Natural

Gas Industries (Equivalent to API 602). API 602:

Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for

the Petroleum and Natural

Gas Industries (Equivalent to ISO 15761).

API 602:

Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for

the Petroleum and Natural

Gas Industries (Equivalent to ISO 15761).

INSPECTION AND TEST

API: API 598:

Valve Inspection and Testing.

API: API 598:

Valve Inspection and Testing. BS 1873:

Steel Globe and Globe Stop and Check Valves (Flanged and Butt-Welding

Ends) For the Petroleum,

Petrochemical, and Allied Industries.

BS 1873:

Steel Globe and Globe Stop and Check Valves (Flanged and Butt-Welding

Ends) For the Petroleum,

Petrochemical, and Allied Industries. API: ISO 15848:

Industrial Valves - Measurement, test, and qualification procedures for

fugitive emissions.

API: ISO 15848:

Industrial Valves - Measurement, test, and qualification procedures for

fugitive emissions.

FLANGE DIMENSION

ASME B 16.5:

Pipe Flanges and Flanged Fittings.

ASME B 16.5:

Pipe Flanges and Flanged Fittings.

WELDED OR THREADED ENDS

ASME B16.25:

Buttwelding ends

ASME B16.25:

Buttwelding ends ASMEB16.11:

Forged fittings, socket-welding and threaded.

ASMEB16.11:

Forged fittings, socket-welding and threaded. ASME B1.20.1:

Pipe threads general purpose.

ASME B1.20.1:

Pipe threads general purpose.

FACE TO FACE AND END TO END

ASME B 16.10:

Face-to-Face and End-to-End Dimensions of Valves.

ASME B 16.10:

Face-to-Face and End-to-End Dimensions of Valves.

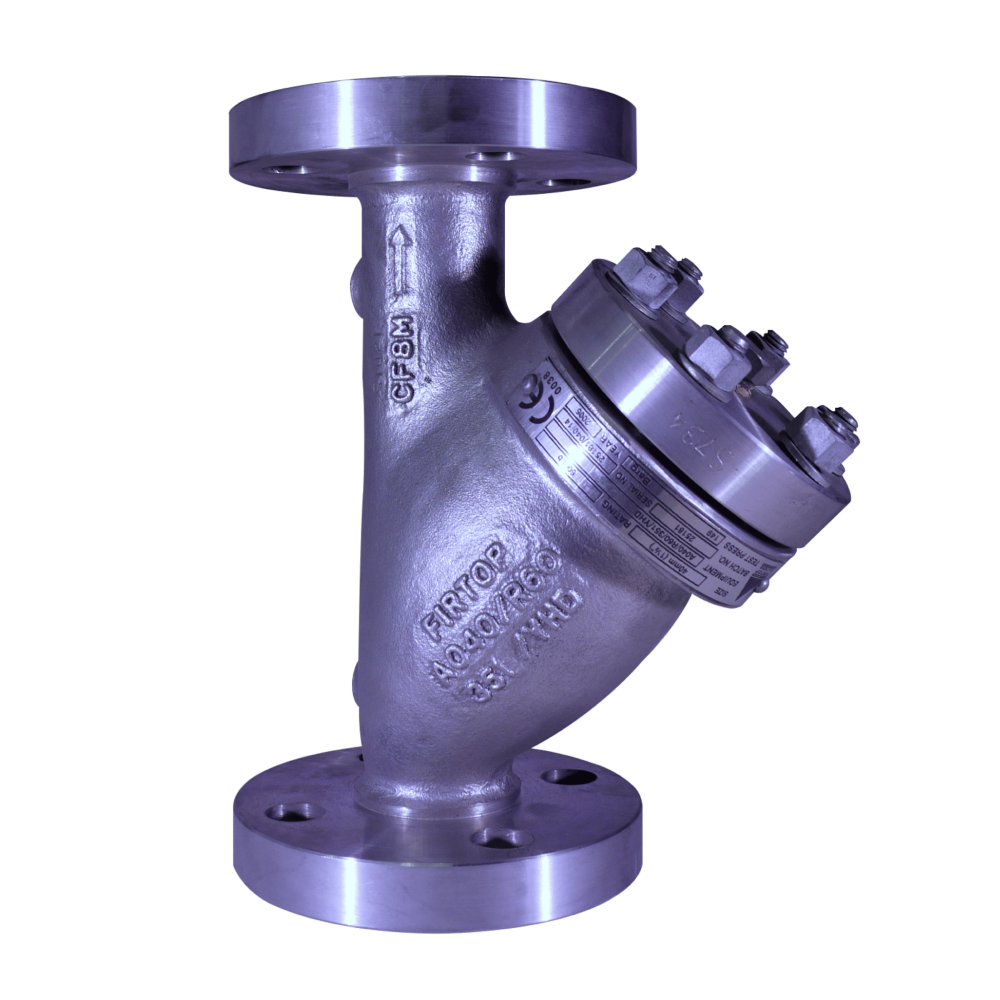

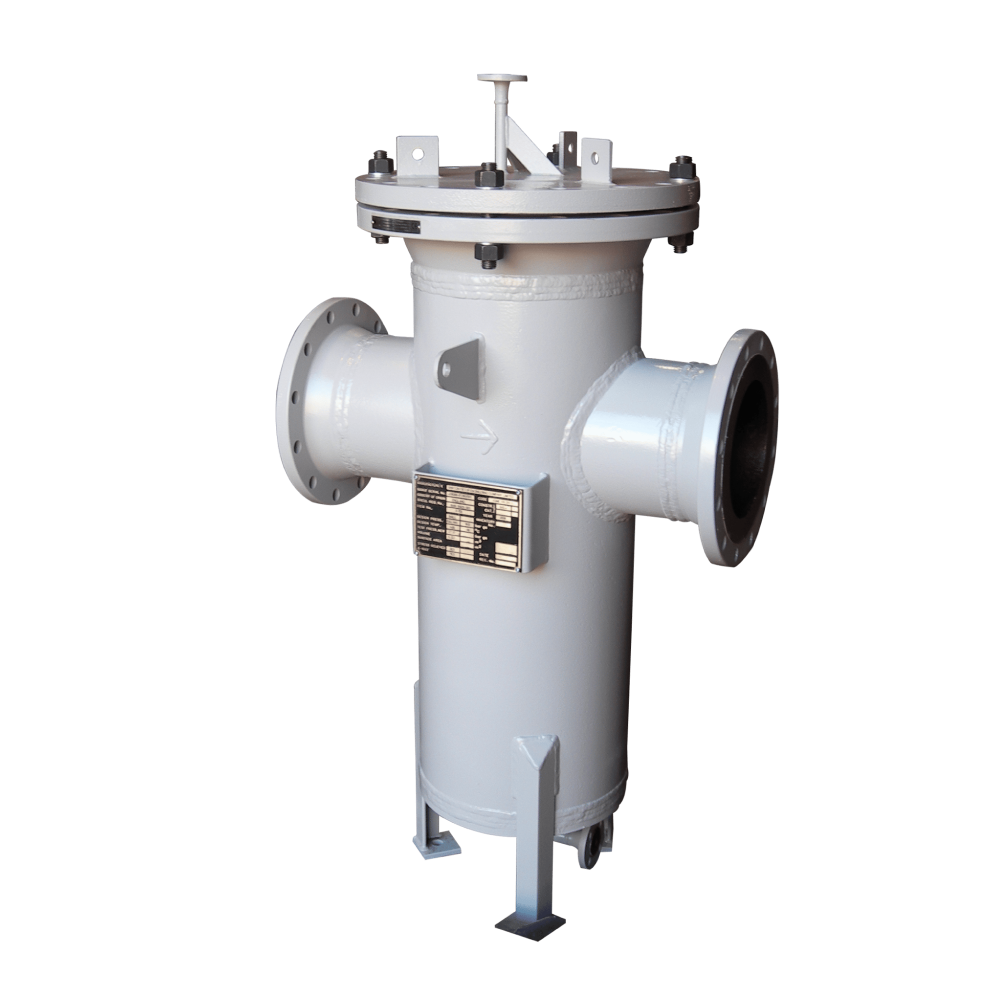

Pressure Safety Valves

Safety valves are a type of automatic valve designed to automatically

open and discharge fluids

when the pressure reaches the designated value, then automatically close again when

the pressure falls below

the designated value. They are used as a safety device to protect equipment,

instrumentation, and piping

from excessive pressure.

Our line-up of full-lift safety valves offers models suitable for steam,

air water, and other

non-hazardous fluids.

We are a specialist supplier of safety relief valves with a complete range of sizes ½

to 20″, rating until

ANSI 2500, and all types of materials such as nodular, carbon steel, low-temperature

carbon steel, stainless

steel, Inconel, Duplex, Super Duplex, and special coating in ECTFE/ Halar.

Our products comply with the Pressure Equipment Directives 2014/68/EU and ATEX

2014/34/EU, as well as with

the regulations in force for each of the sectors and corresponding applications.

They are designed and manufactured under strict quality control ISO 9001:2015.

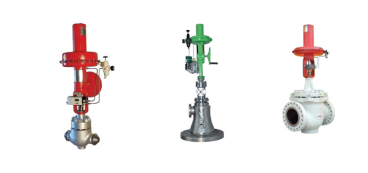

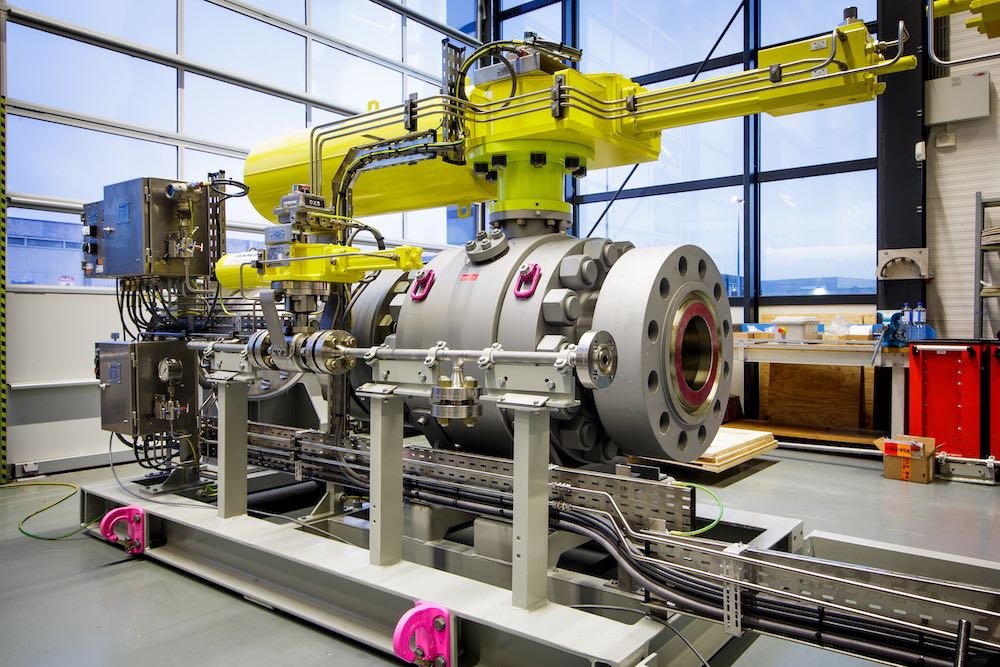

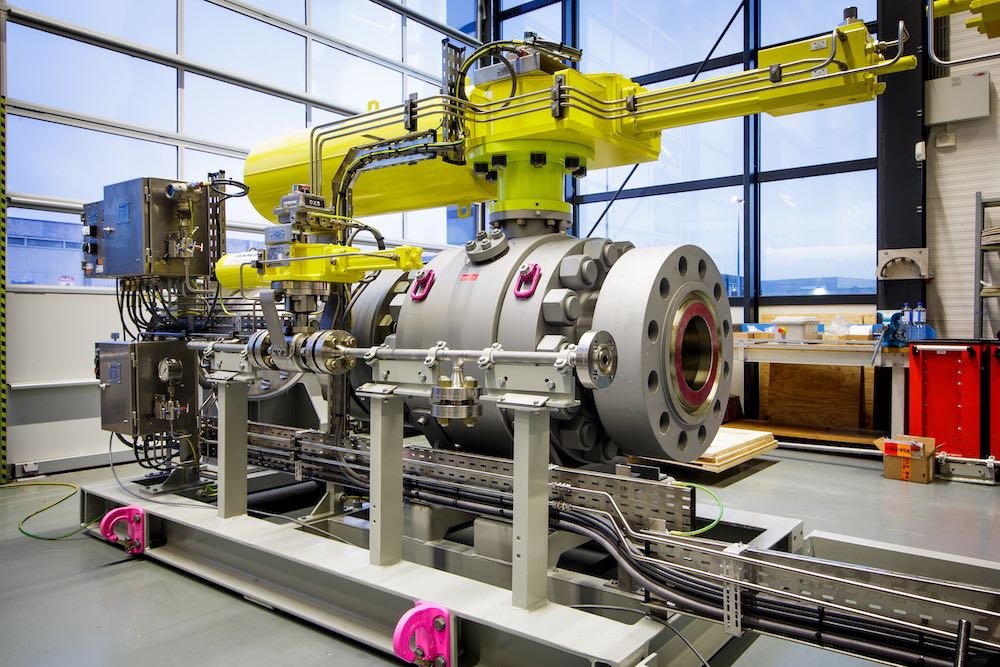

Custom Made Engineered Valves

We offer a complete range of application-specific valves from premier

legacy brands.

Our highly engineered valves are known to be durable, long-lasting, and field-proven

in the most severe

conditions.

Our tailor-made valves are available in both forged and cast exotic

materials, with short

delivery times.

Pipe, Fittings and Flanges

We are supplying pipe, butt weld fittings, socket weld & threaded

fittings, and flanges in a

variety of types, sizes, schedules, and pressures and we can deliver orders timely

to meet your project time

requirements and offer expedited lead times for special or custom requests.

Our supplies include, but are not limited to, carbon steel, stainless

steel, PVC S80, CPVC S80,

and specialty alloy materials. Our highly trained staff will help you with your

pipes, flanges, fittings,

structural shapes, and related components.

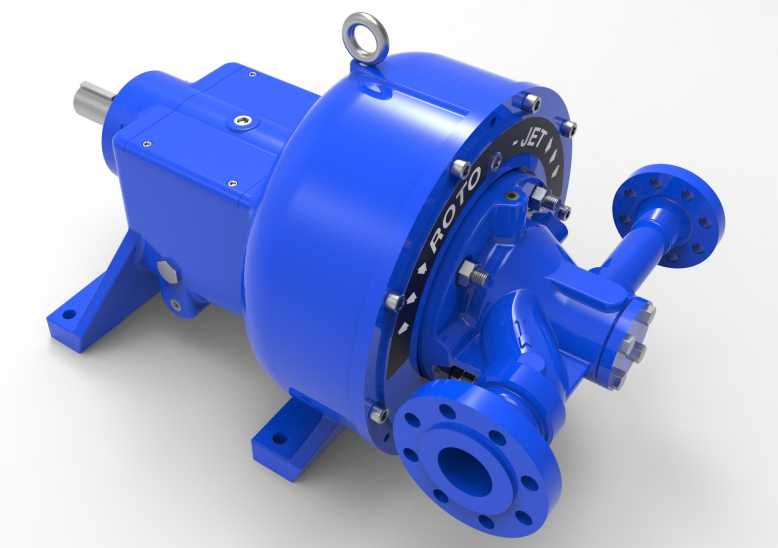

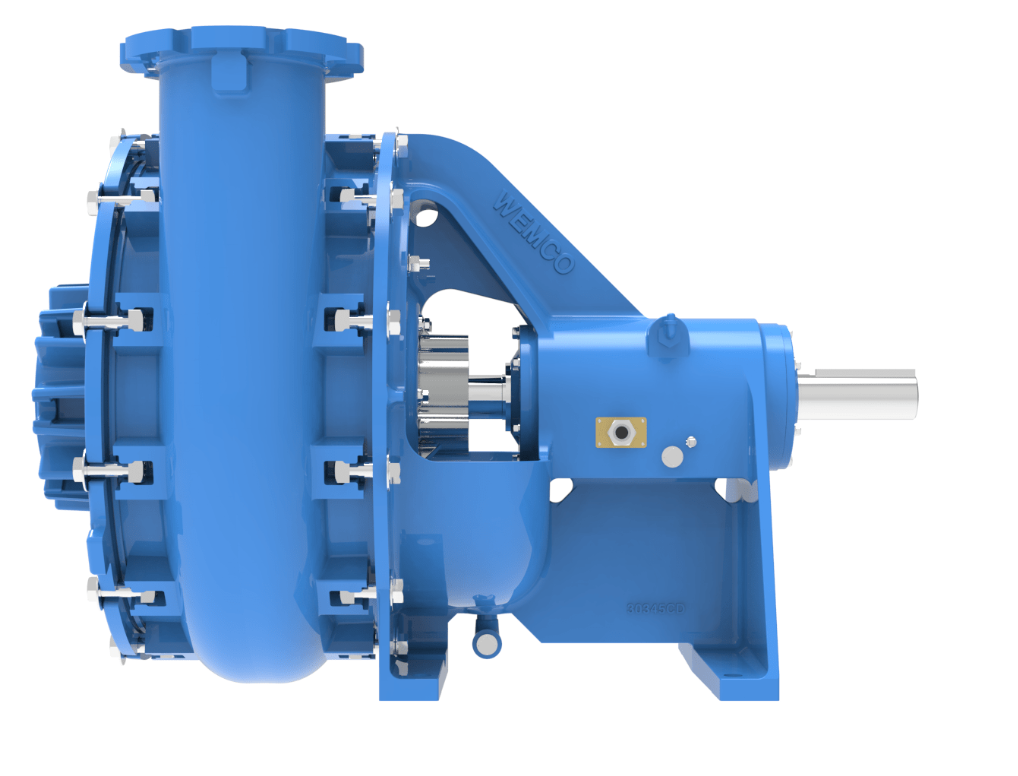

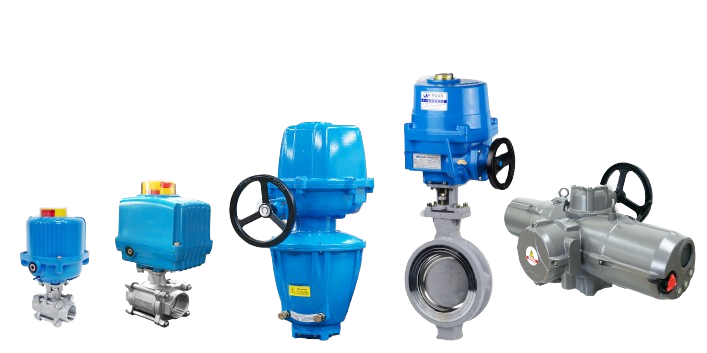

Actuators

We supply actuators that enable you to take control of your plant fluids

with reliability and

safety. Anytime, anywhere.

If you are working with fluids such as gas, oils, high-pressure air, and

water need zero leaks

and control in any situation.

We are laser-focused on supplying high-performance actuators, built with

the technology for your

needs in industrial, commercial, and residential applications. We offer actuators,

actuated valves, and

completely assembled kits to help you waste no more resources

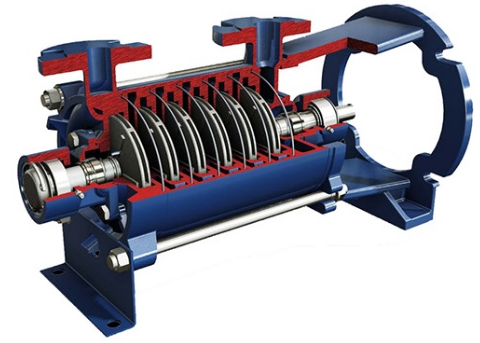

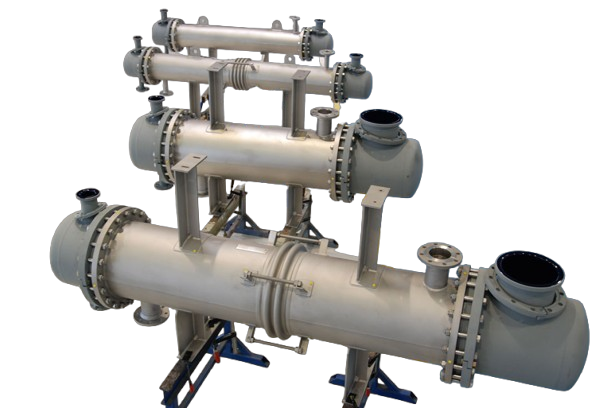

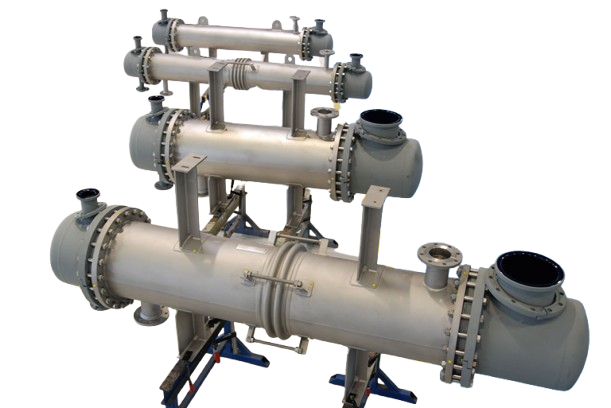

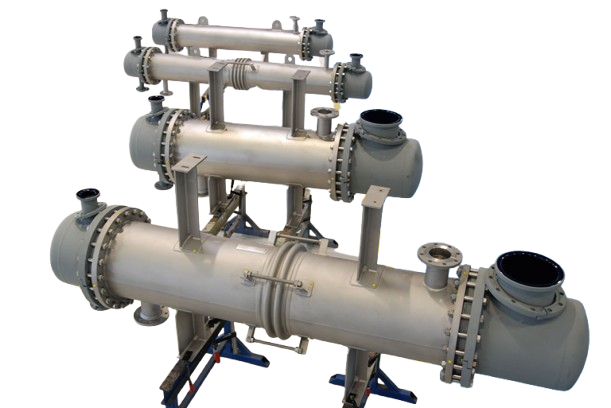

Heat Exchangers and Condensers

We, Powerline offer a full range of Heat exchangers and Condensers

standardized product lines

for an optimal price/quality ratio as well as customized designs for the most

demanding duties in oil & gas,

petrochemical, power generation, marine, refrigeration, and many other industries.

Cost-efficient and reliable solutions

Shell & Tube heat exchangers are the most common designs for many

applications. We provide a

wide variety of applications based on the most suitable design and materials to

ensure a cost-efficient and

reliable solution.

Heat Exchanger offers major advantages for applications where oil or air

has to be cooled. The

enlarged surface on the shell side compensates for the lower heat transfer value of

such media. It is ideal

for customers who require a reliable, low-maintenance, and high-quality heat

exchanger that is also

long-lasting and takes up minimum space. Due to its robust design, the heat

exchangers have good resistance

to vibrations and shock loads.

Heat Exchangers & Condensers

We, Powerline offer a full range of Heat exchangers and Condensers

standardized product lines

for an optimal price/quality ratio as well as customized designs for the most

demanding duties in oil & gas,

petrochemical, power generation, marine, refrigeration, and many other industries.

Cost-efficient and reliable solutions

Shell & Tube heat exchangers are the most common designs for many

applications. We provide a

wide variety of applications based on the most suitable design and materials to

ensure a cost-efficient and

reliable solution.

Heat Exchanger offers major advantages for applications where oil or air

has to be cooled. The

enlarged surface on the shell side compensates for the lower heat transfer value of

such media. It is ideal

for customers who require a reliable, low-maintenance, and high-quality heat

exchanger that is also

long-lasting and takes up minimum space. Due to its robust design, the heat

exchangers have good resistance

to vibrations and shock loads.

Croll Reynolds is an engineering firm specializing in the research,

design, and manufacture of

process vacuum systems, combination liquid ring/ejector systems, thermo compressors,

vacuum chillers and

pollution control systems.

Complies to API 675

Complies to API 675